Quality Control

Interview

KST has it's own 89000 square meters industrial park& 200 square meters independent high-end laboratory,and more than 50 professional R&D and QC staffs.

Our quality department, as the company's core competitiveness of production and technology testing and monitoring terminal, built on the basis of ISO 9001 quality management system , customer-oriented. With IQC, IPQC, FQC, OQC, reliability&pro-environmental management functional organization, and fully trained professional inspection team of more than 20 staff. Equipped with French YOKOGAWA, EXFO and other brands of precision OTDR optical time domain detector, combined with the company's ERP system, can achieve 100% monitoring and testing of products in each process, and ensure the traceability of all. At the same time, we carry out periodic TDR improvements with production and technical departments, we strictly and comprehensively escort every meter of optical fiber cable, to commit to the concept of winning the market with superior quality and service.

R&D QC Team

Our laboratory equipped with almost 100set state-of-the-art optical fiber cable experimental equipment,such as tension testing machine;filtration efficiency machine tester;UV accelerated weathering tester water penetration testing machine;Halogen Acid Gas Release measuring device;vibration testing machine;Fire retardant testing machine;High and low temperature testing machine;Winding testing machine;bending testing machine;flexing testing machine;impact resistance testing machine;abrasion testing machine;crush testing machine;fiber geometric parameter testing machine ,etc.

Our R&D and QC staffs are all high qualified and more than 5 years work experience we have nearly 50 national invention patents.

Our powerful experimental configuration provides customers with strong customization ability and quality assurance.

media section

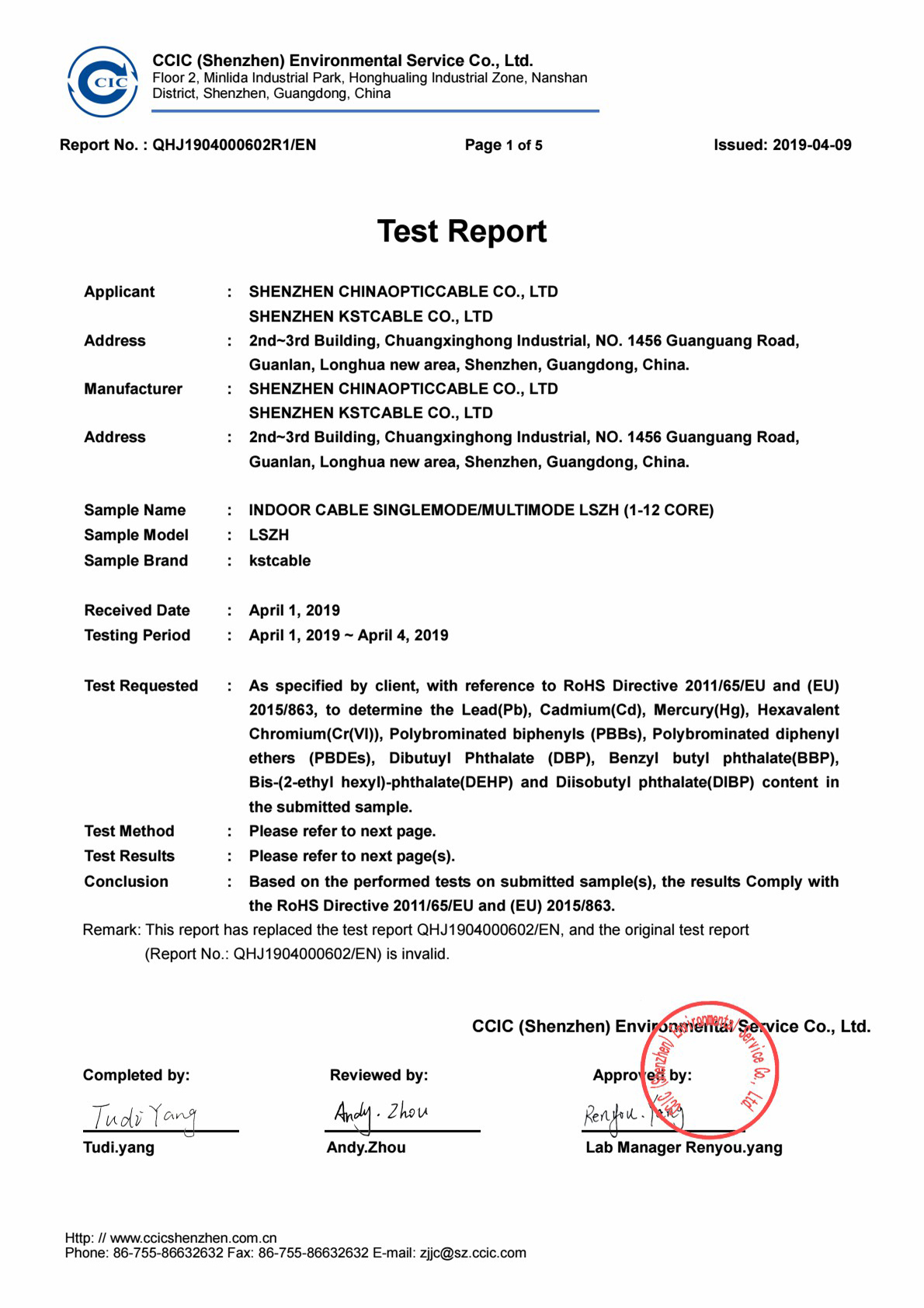

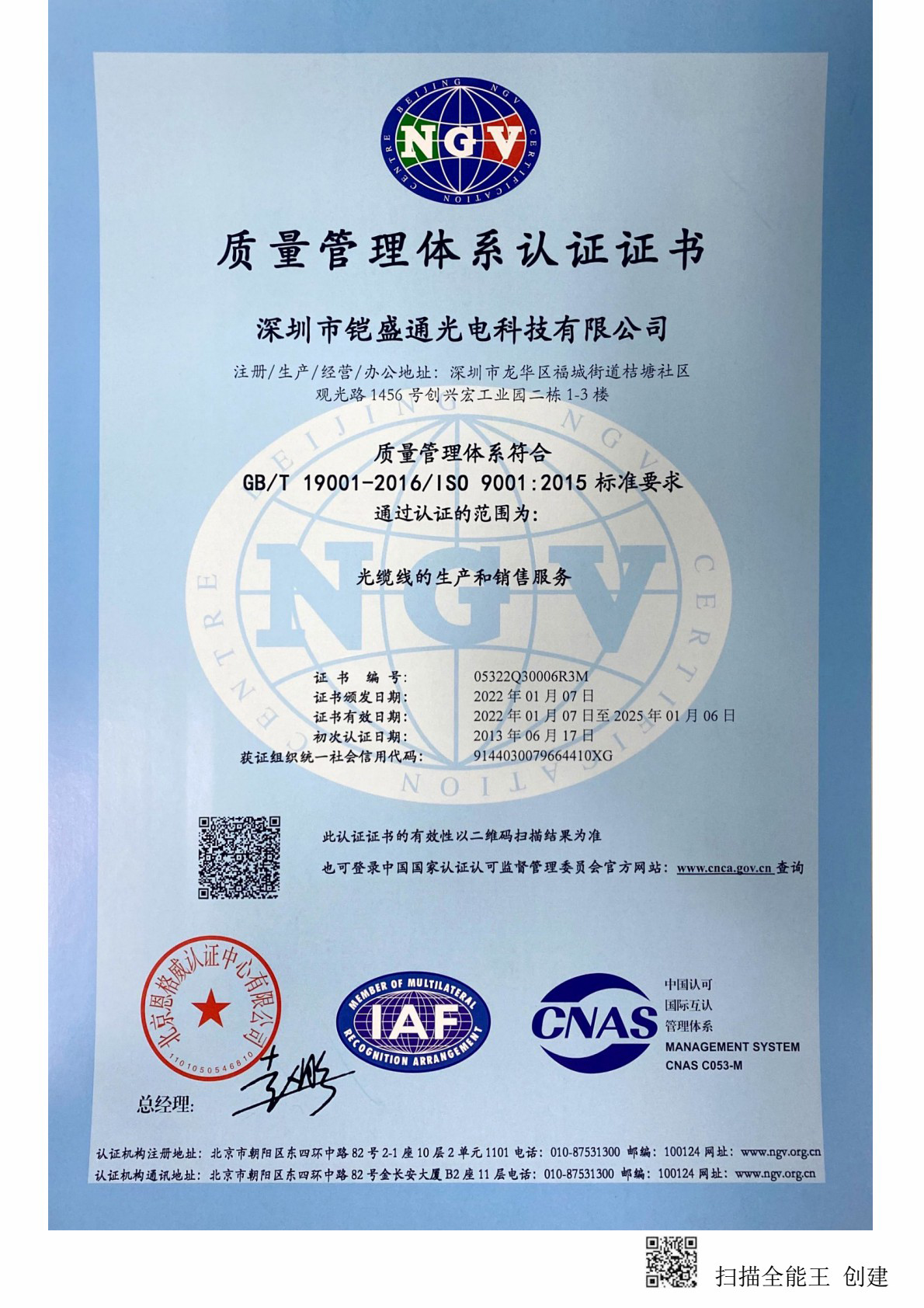

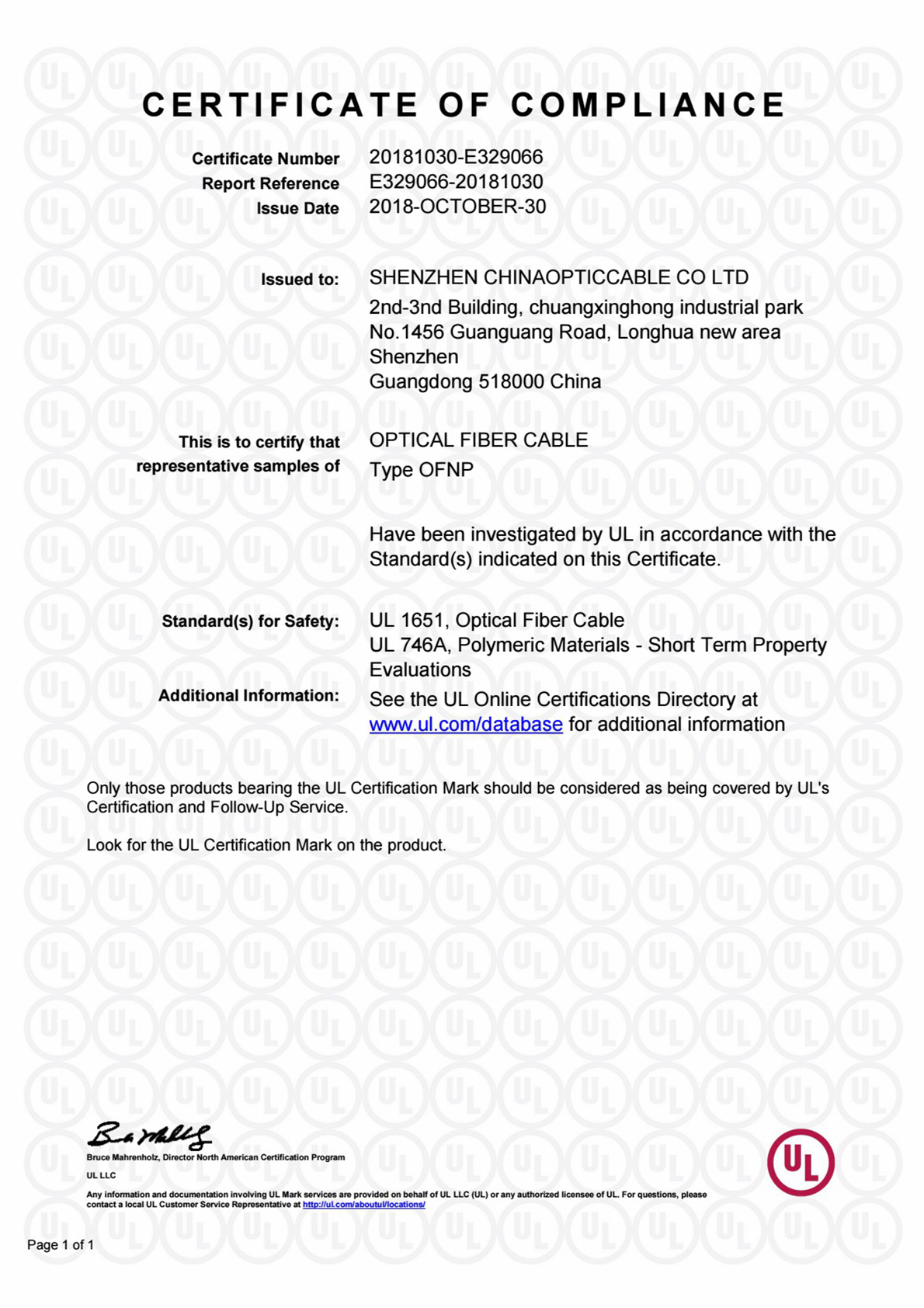

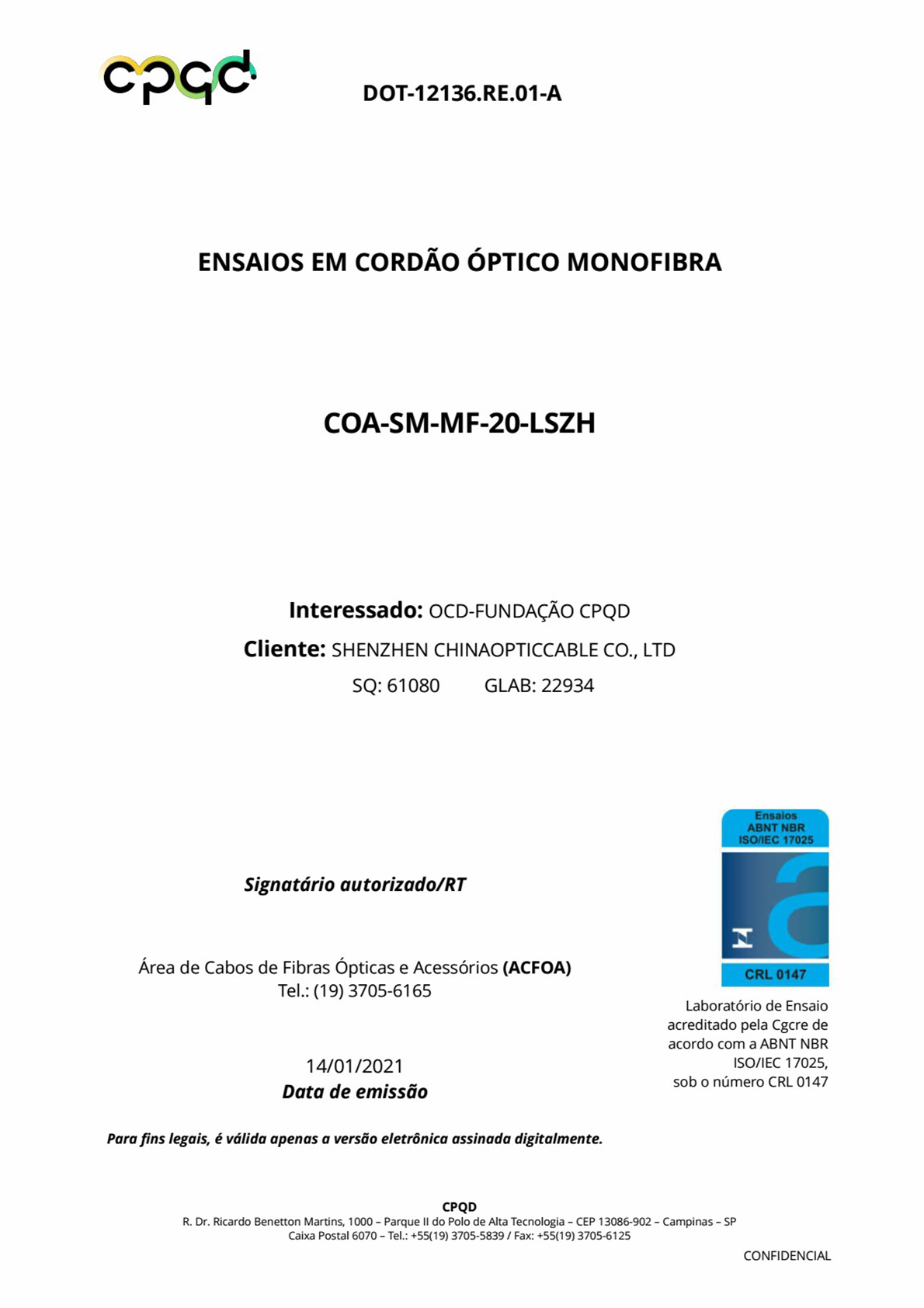

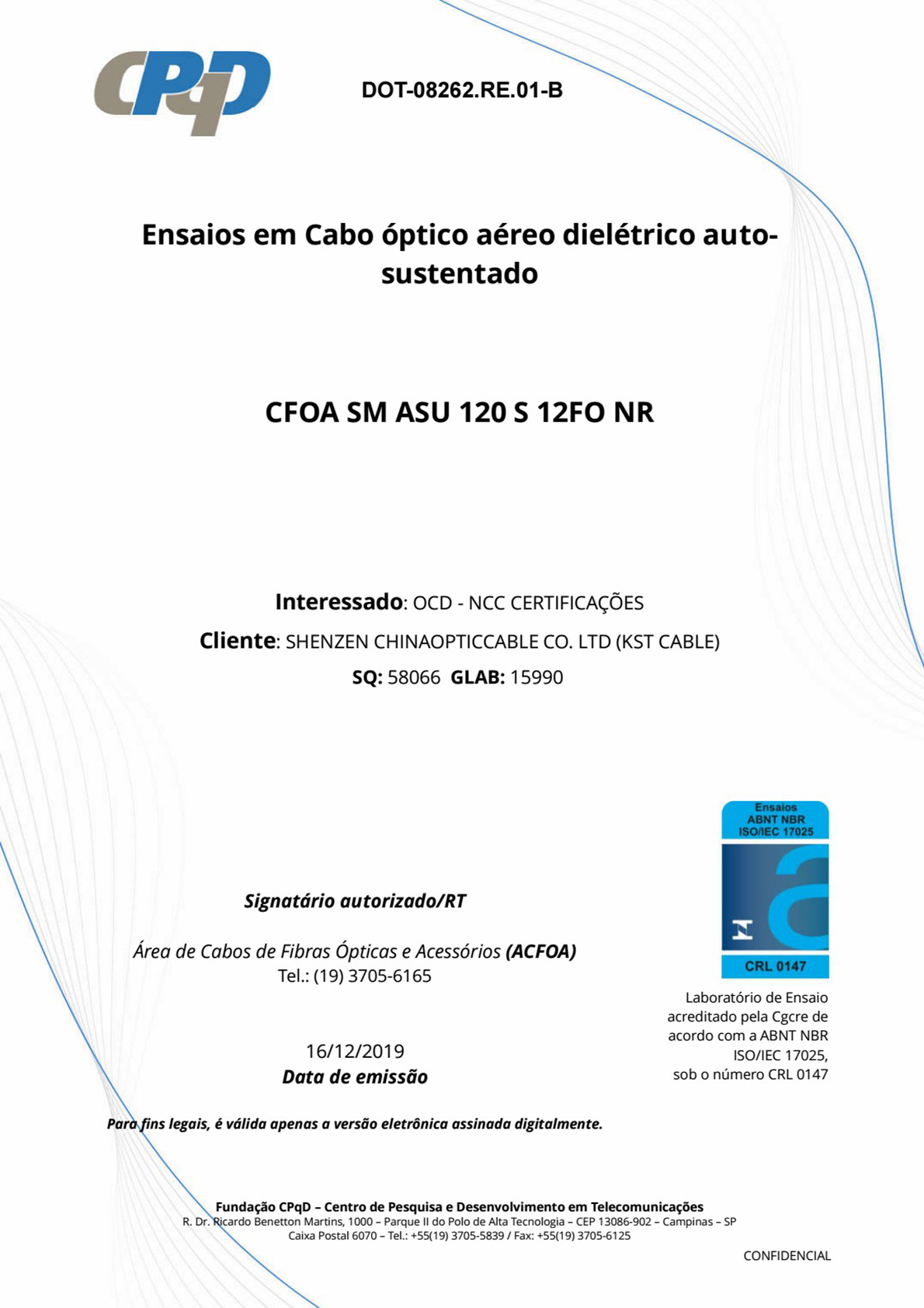

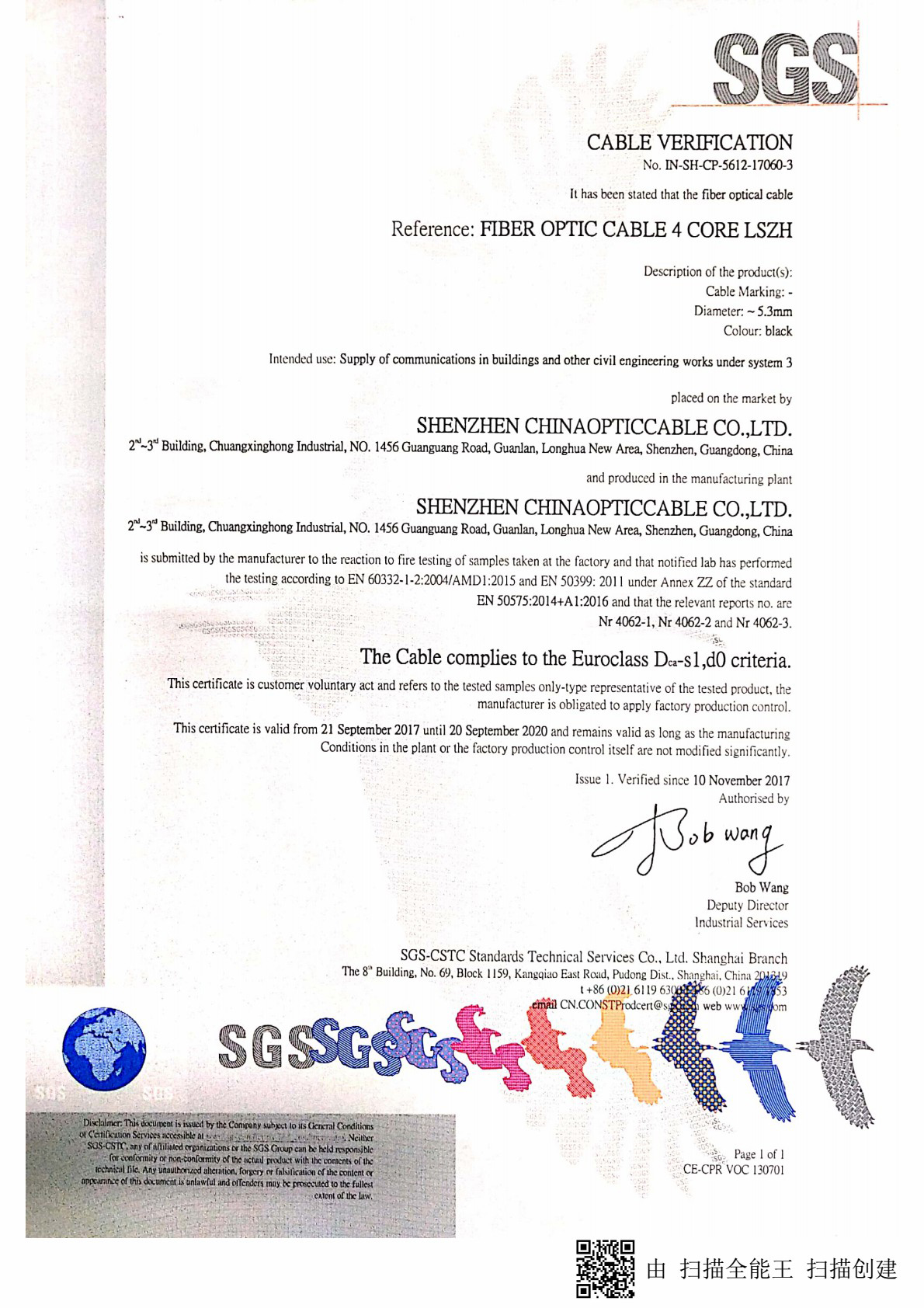

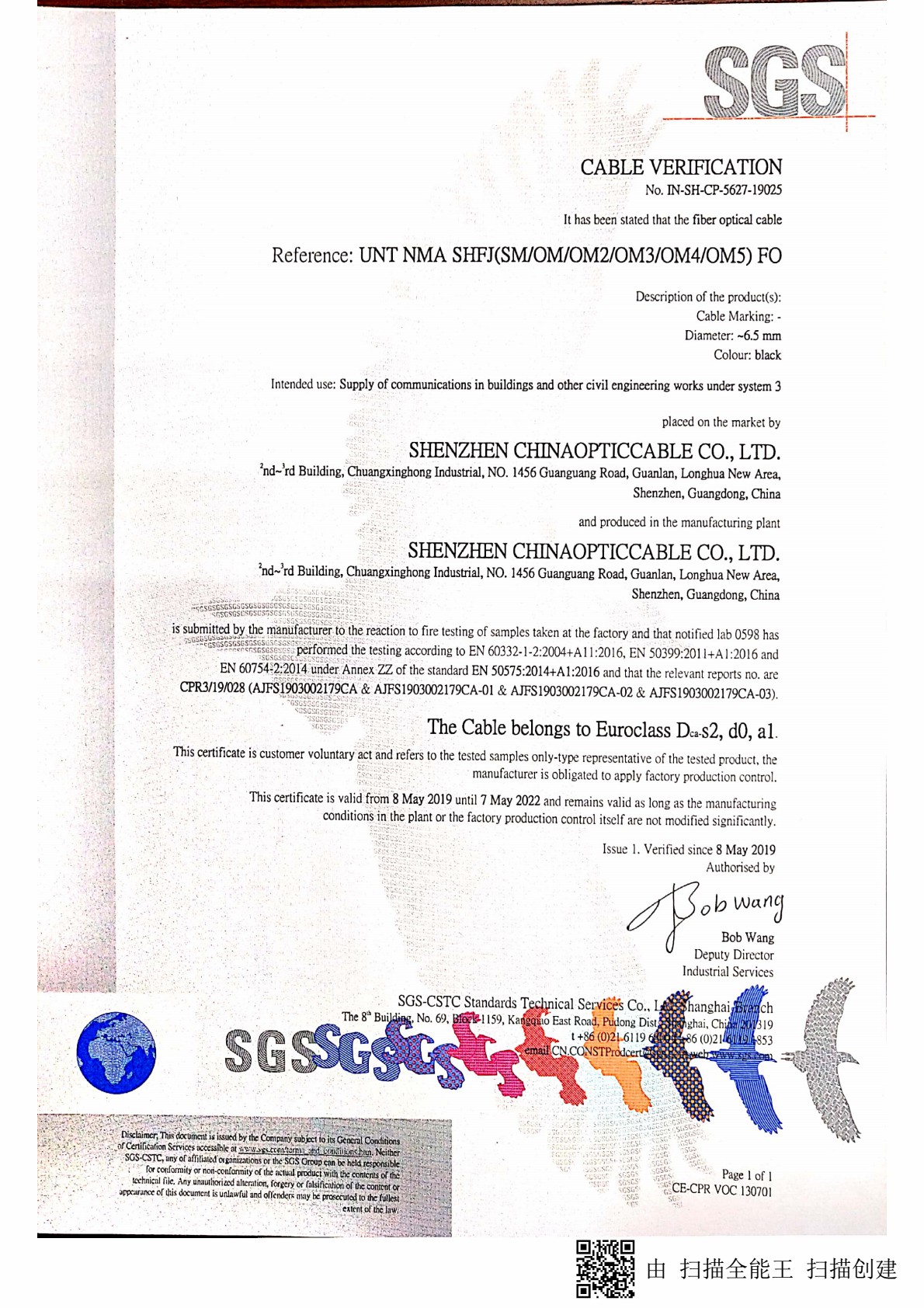

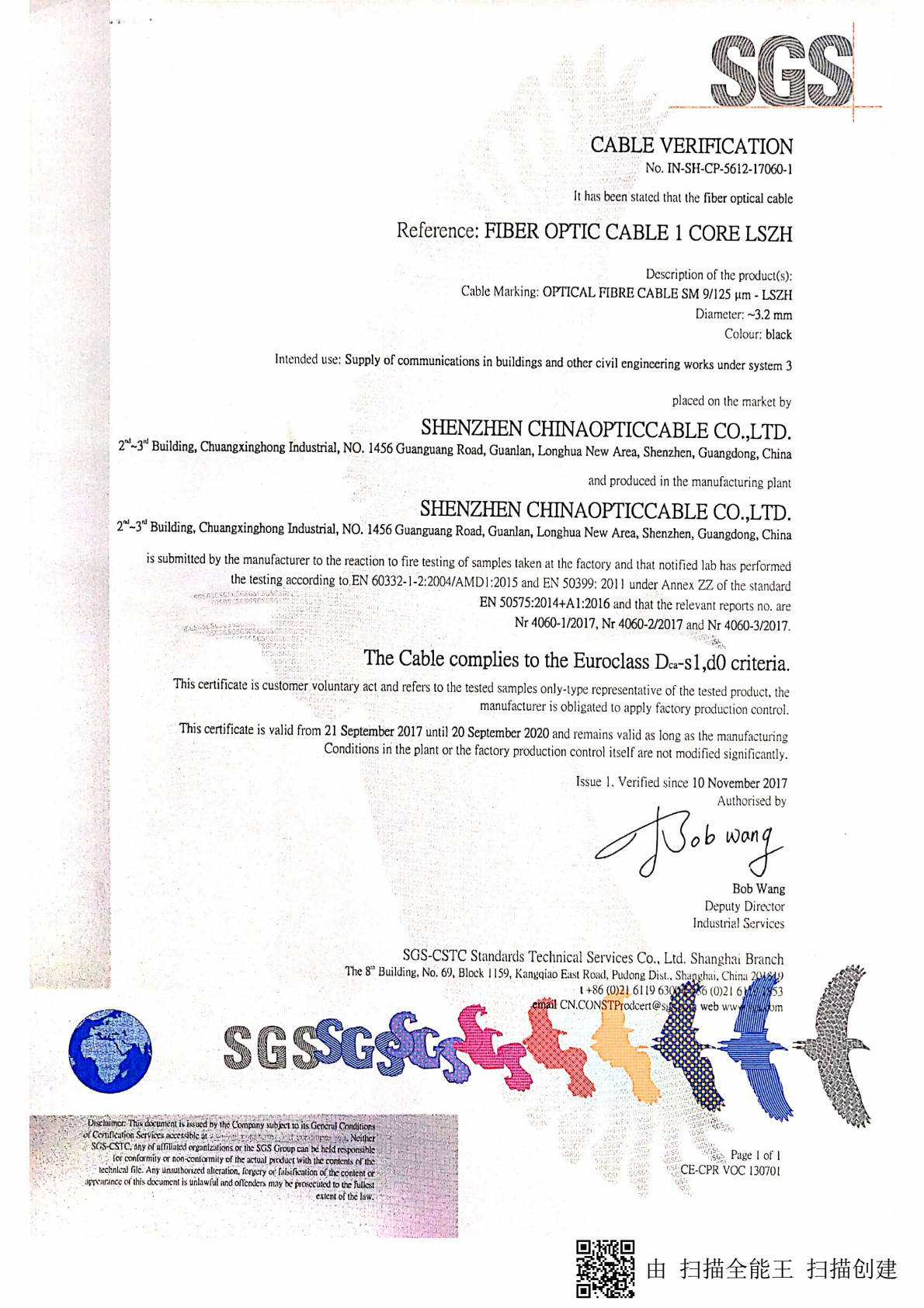

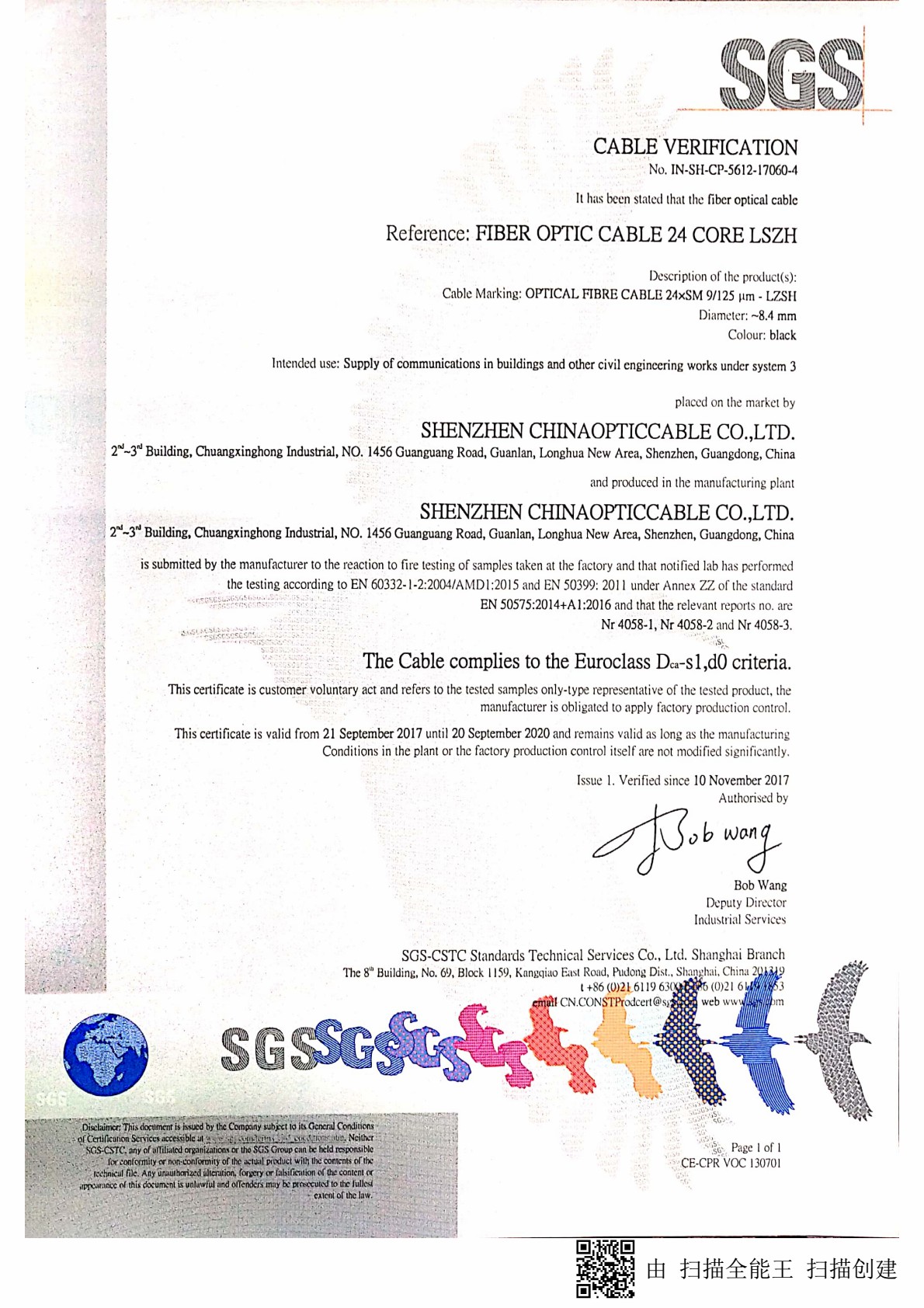

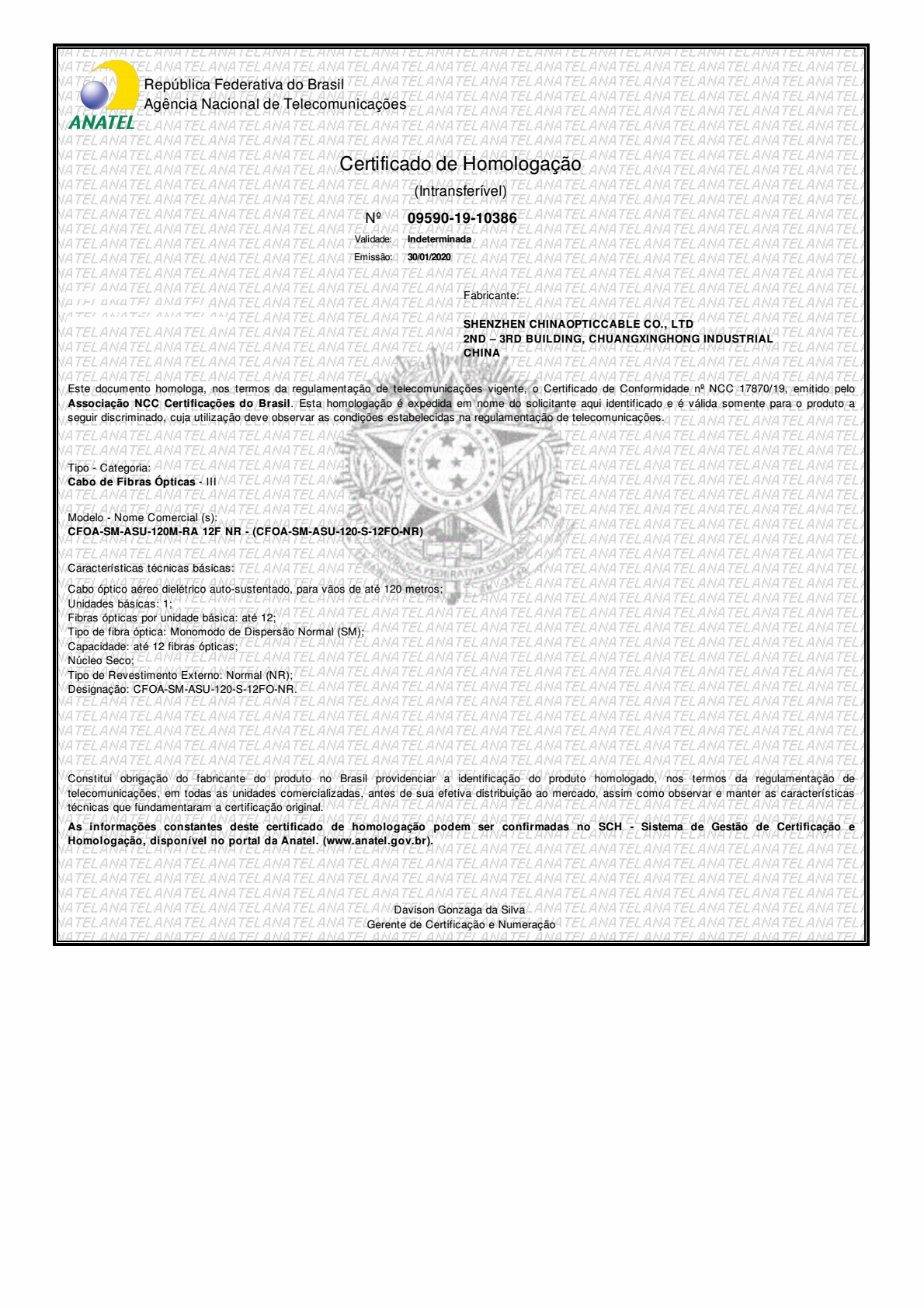

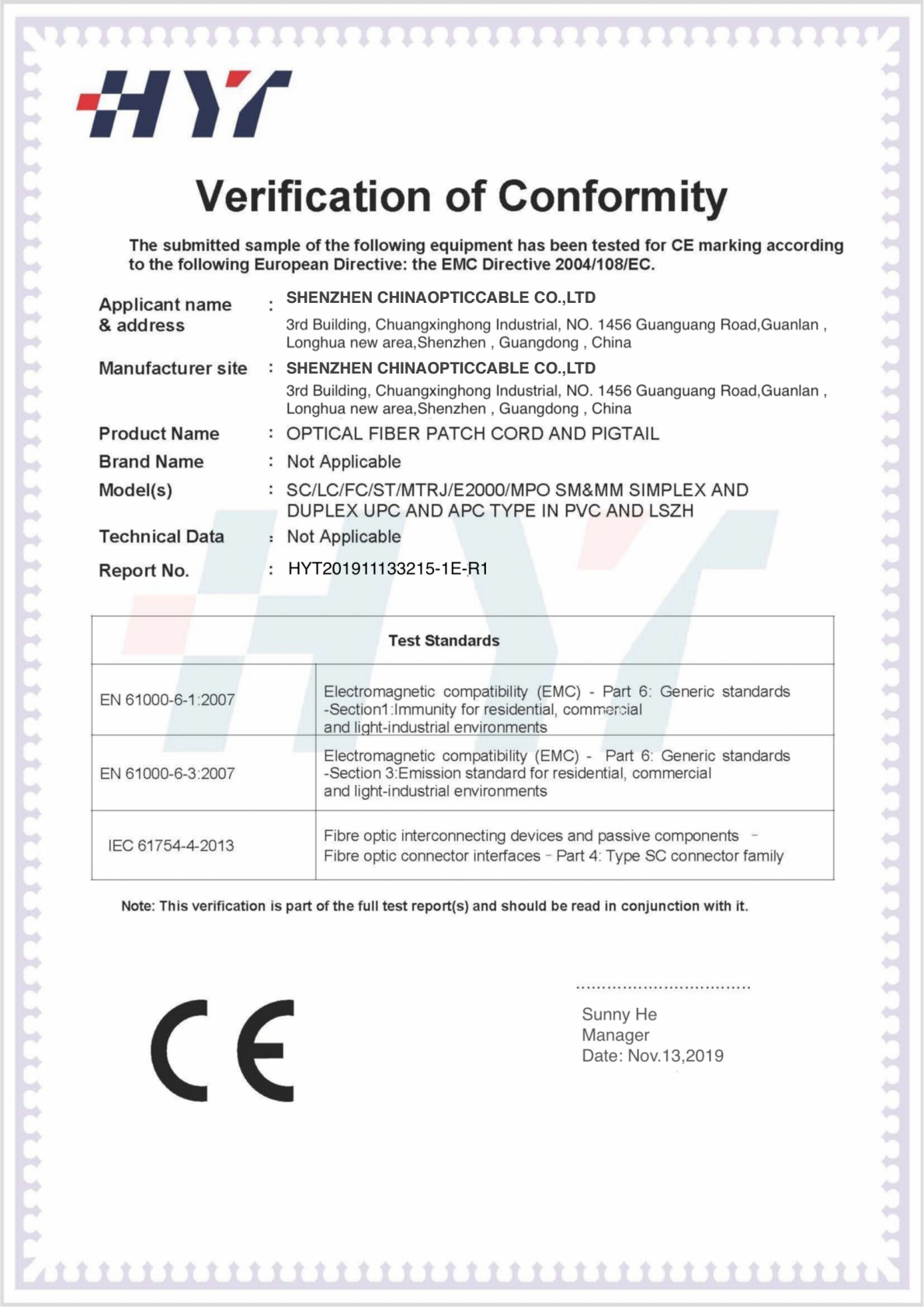

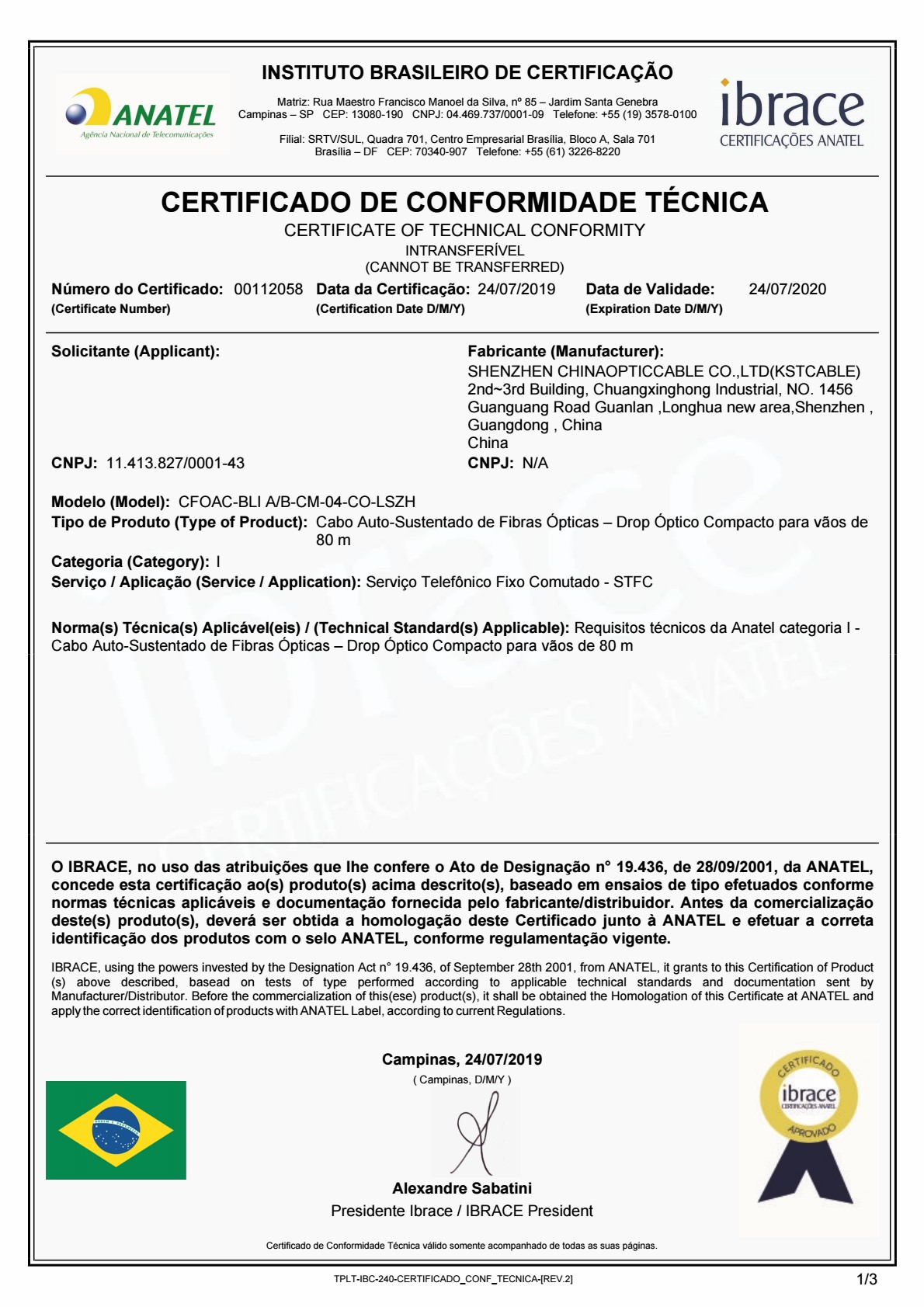

Certificate

Patent

Number |

Patent name |

Patent number |

Patent date |

Hyperlink |

Patent 1 |

A water seepage test system for special communication optical cable |

ZL 2020 1 0785262.9 |

20200806 |

|

Patent 2 |

Special communication optical cable processing and production system and its processing technology |

ZL 2019 1 0770550.4 |

20190820 |

Patent 2 |

Patent 3 |

A paste spraying device used for optical cable production |

ZL 2019 2 1341165.X |

20190819 |

Patent 3 |

Patent 4 |

Vertical combustion experimental system used for the flame retardant test of special communication optical cable |

ZL 2019 1 0769643.5 |

20190820 |

Patent 4 |

Patent 5 |

A new type of soft elevator optical cable |

ZL 2014 2 0718513.1 |

20141126 |

Patent 5 |

Patent 6 |

A new type of small seamless steel pipe optical cable |

ZL 2014 2 0718513.1 |

20141126 |

Patent 6 |

Patent 7 |

A new bite and termite fiber cable |

ZL 2014 2 0730161.1 |

20141126 |

Patent 7 |

Patent 8 |

A new type of reinforced submarine climbing optical cable |

ZL 2014 2 0730295.3 |

20141126 |

Patent 8 |

Patent 9 |

A new type of reinforced submarine climbing optical cable |

ZL 2014 2 0718035.4 |

20141126 |

Patent 9 |

Patent 10 |

A new type of multi-core mini-unit structural optical cable |

ZL 2014 2 0730233.2 |

20141126 |

|

Patent 11 |

A new type of optical fiber-to-home optical cable |

ZL 2014 2 0718576.7 |

20141126 |